The Kawasaki duAro Robot’s ability to be quickly and infinitely re-configurable, master and slave to the machinery components and simultaneously communicate with a network all while operating two SCARA arms makes this machine more than unique.

After 2 years of work, we have developed a Pick’n Place system using a Kawasaki collaborative robot. Kawasaki produces the perfect COBOT for this application, the duAro Dual Scara Collaborative Robot. By integrating our C-100 highly customizable controller, we now have a machine that can do “Direct Packaging of 4000 Bottles per hour“. Our C-100 Family of controllers range from simple control of an environment to complex machines with multiple motors, encoders and analog I/O. The C-100 is an “out of the box” controller designed to be flexible, easy to re-task and interfaces with everything we have used with it from Pumps to Formers and from Bottle Fillers to Traffic Control System.

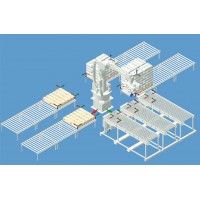

The RBC-1700 is a unique machine with the ability to adapt to a variety of production needs. This machine can handle a very wide range of products. Here we are only showing one product to give you an idea of how the machine works. The concept is a “direct to packaging” approach to manufacturing.

RBC1700 Pick and Place COBOT

- Brand: Bransom Tech Services

- Product Code: RBC1700

- Availability: In Stock

-

$79,500.00

Related Products

Kawasaki duAro1 collaborative robot

The “duAro1” dual-arm collaborative SCARA robot is an innovative robot that works safely and efficie..

$42,000.00

BTS Robotic Palletizing Workcell

Includes:Kawasaki CP180L 4-Axis Robot Up to 2080 Moves per Hour w/130kg loadKawasaki E03 Regenerativ..

$175,900.00

Tags: packaging, kawasaki robot, duaro, cobot